Sheet metal/Tube fabrication is a manufacturing method that involves cutting and bending sheets/tubes of metal to form different shapes.

Sheet metal/Tube fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

Available sheet metal/Tube fabrication processes

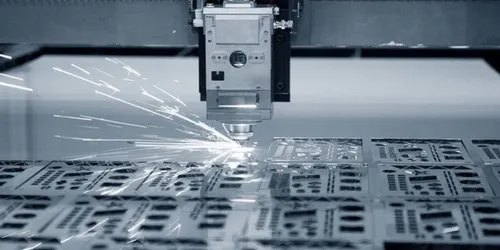

Laser cutting –

Is a process that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes. Its unique design and operation make it highly accurate, especially when cutting intricate shapes and small holes.

CNC laser cutting is a non-contact, thermal-based process. A CNC laser cutter features a laser head containing a laser focusing lens and a nozzle. Through the nozzle, this head and lens assembly focuses a laser beam — a column of very high-intensity light on the workpiece, melting and cutting the workpiece to form the desired shape. CNC lasers employ compressed gas to cool the focusing lens and expel the vaporized metal out of the workpiece.

Tube Bending –

CNC pipe bending machines will produce small radius bends, large-radius bends, and oval bends on the same part. They are precision machines that ensure a high level of productivity and repeatability. CNC pipe benders can be used to create complex tubular sections, as they can control the pipe automatically and position it accurately.

They are composed of three axes and a carriage driven by a servo motor. The carriage automatically positions the distance between the elbow and its plane. The CNC pipe bender does not contain hydraulic or pneumatic functions, so it has higher repeatability and operability. These machines can be used in many industries including automobiles, shipbuilding, and railways. There are three types of CNC shaft bending machines: