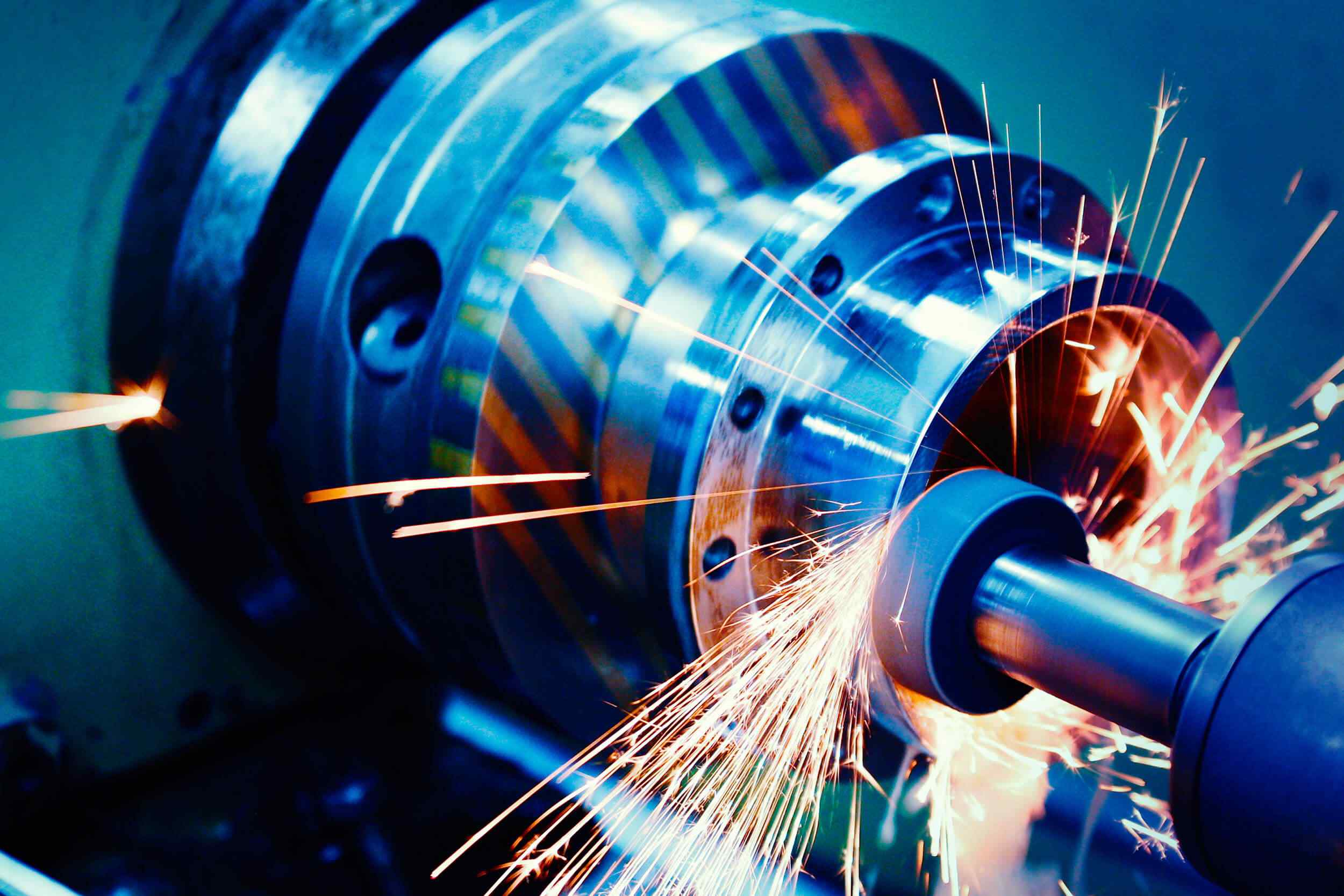

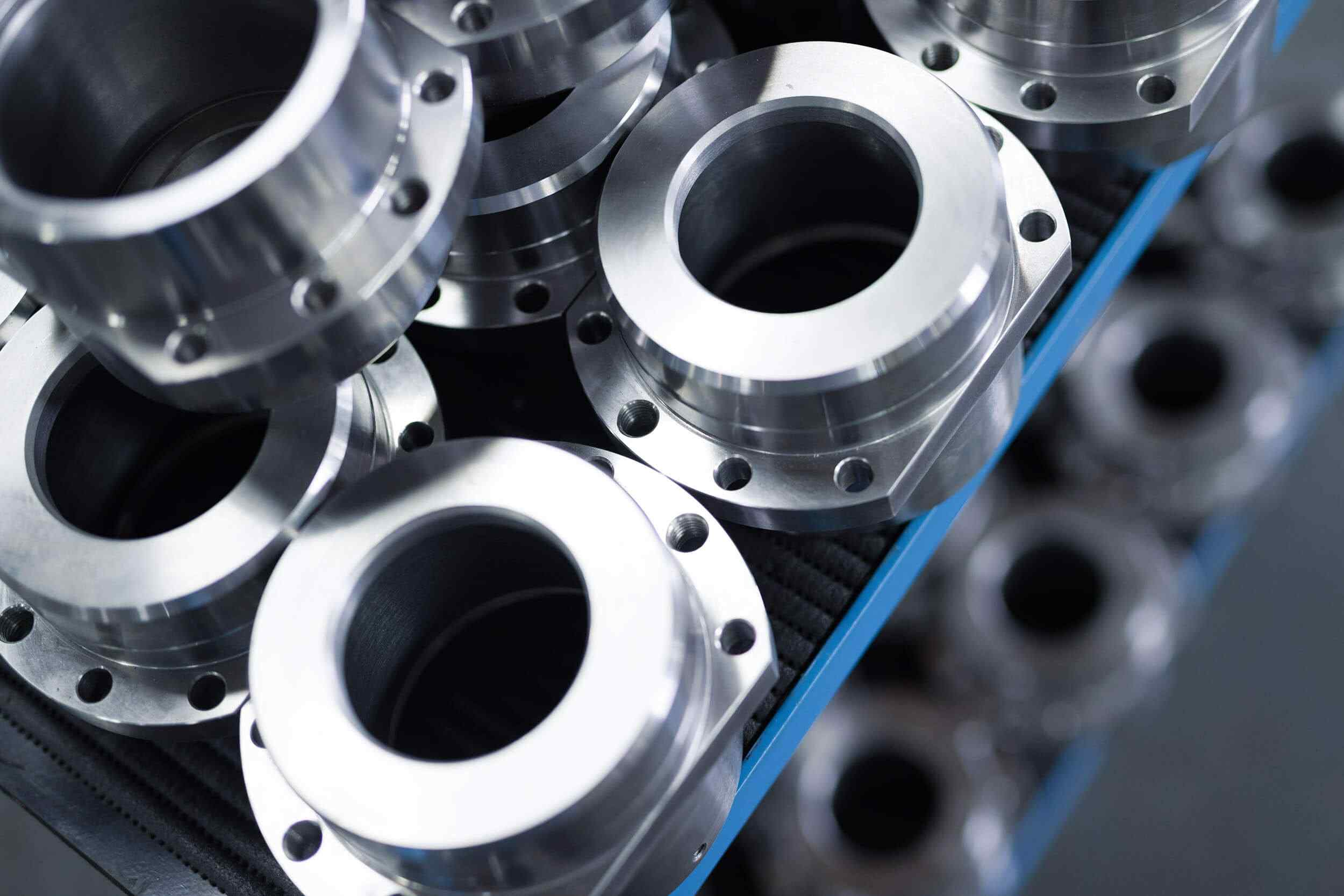

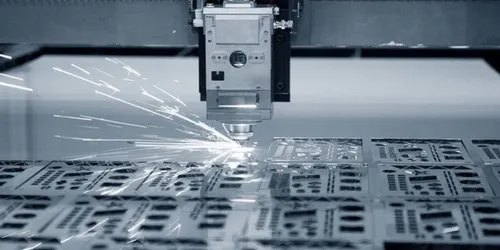

CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid block with a variety of cutting tools.

Tools

Electrical discharge machining (EDM) has been the solution for machining intricate parts and materials resistant to traditional machining methods or by necessity of design. This non-conventional process is one of the most efficient and cost-effective manufacturing methods since it delivers an extraordinary level of accuracy and unmatched precision. It works on parts that are electrically conductive, regardless of their hardness. EDM allows manufacturers to create complex shapes from hard materials such as titanium, stainless, steels, tool steel and other hardened alloys. There are three types of EDMs: Fast hole drilling EDM (Hole Poppers), Sinker EDM (Sinkers), and Wire EDM (Wires). However, for this article, we'll be looking in depth at Wire EDM.

Sheet metal/Tube fabrication is a manufacturing method that involves cutting and bending sheets/tubes of metal to form different shapes.